Photon Mono X 3D printer review: The best resin printer we’ve tested under $1,000

Our Verdict

If the $three,499 Course three is too much for your budget, the Photon Mono X 3D printer is a lower-cost alternative. This resin-based printer is fast and produced some high-quality prints, albeit with a few print failures in our testing.

For

- Large print size for depression cost

- Fast prints

- High-quality prints

Against

- SLA printing is yet a mess, stinky business

- Slicing software produces inconsistent supports

- Some print failures

Tom'southward Guide Verdict

If the $3,499 Form three is too much for your upkeep, the Photon Mono X 3D printer is a lower-cost alternative. This resin-based printer is fast and produced some high-quality prints, albeit with a few print failures in our testing.

Pros

- +

Large impress size for low cost

- +

Fast prints

- +

High-quality prints

Cons

- -

SLA press is yet a mess, stinky business

- -

Slicing software produces inconsistent supports

- -

Some print failures

Photon Mono X 3D printer: Specs

Cost: $599

Size: 18 by 11.4 by 10.6 inches

Print Size: 9.6 by seven.5 by 4.6 inches (331 Cu. in)

Type: SLA Resin

We've seen the 3D printer market alter over the past few years, with prices falling and the quality of the prints improving. The AnyCubic Photon Mono X continues this excellent trend past offering SLA printing for $599. That's not the cheapest price we've seen for an SLA printer, but information technology's definitely an attractive one for a devicer that produces loftier-quality prints and has earned a place among the best 3D printers we've tested.

As office of our AnyCubic Photon Mono X review, we also tested the Anycubic Wash and Cure Plus automobile, a carve up device that can wash the prints the Photon Mono 10 produces and cure them to harden the resin with a serial of UV lights.

Photon Mono Ten 3D printer review: Price and availability

The Photon Mono X is available now for $559 from Amazon. The Wash and Cure Plus costs $249.99 from Amazon.

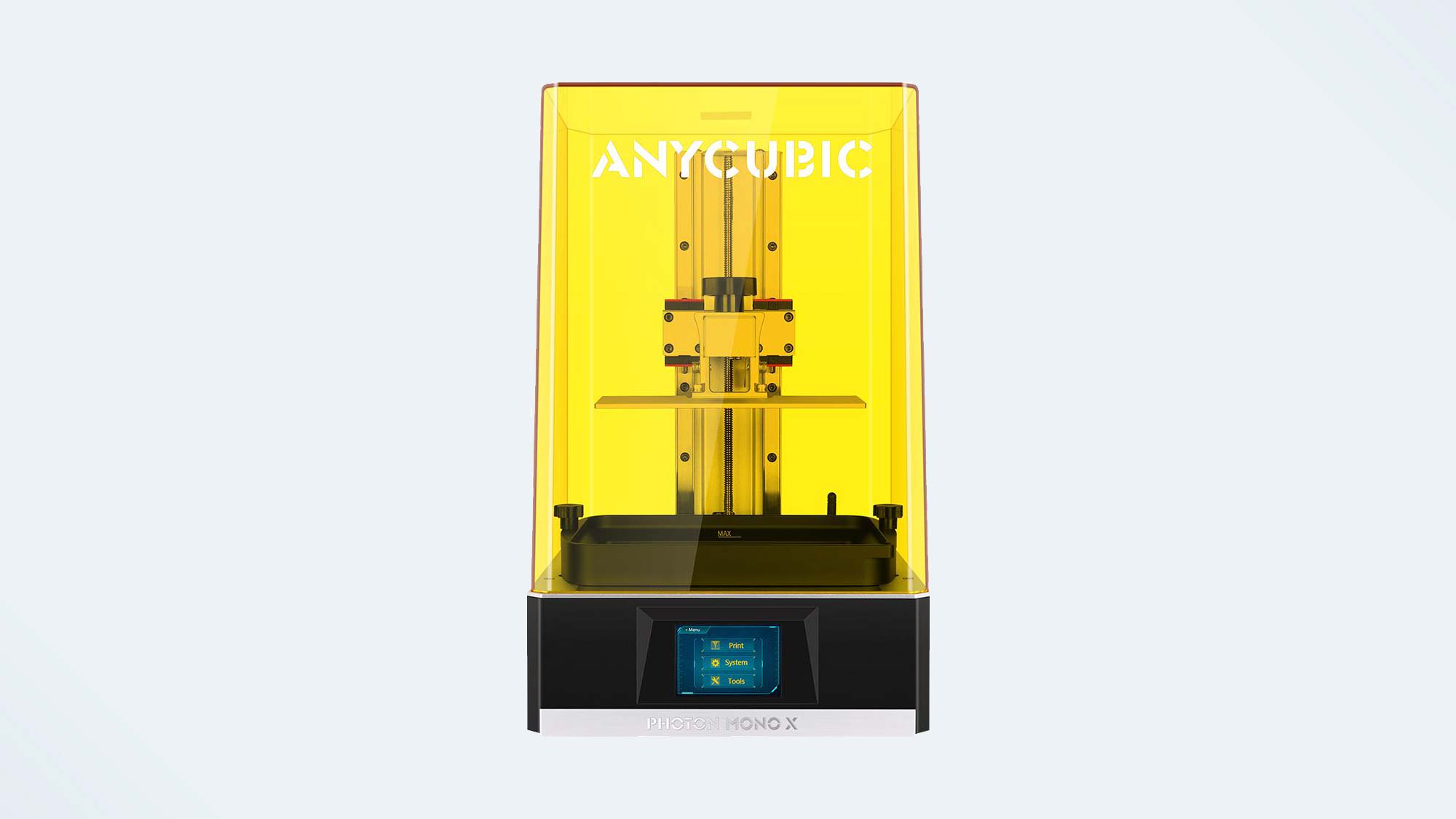

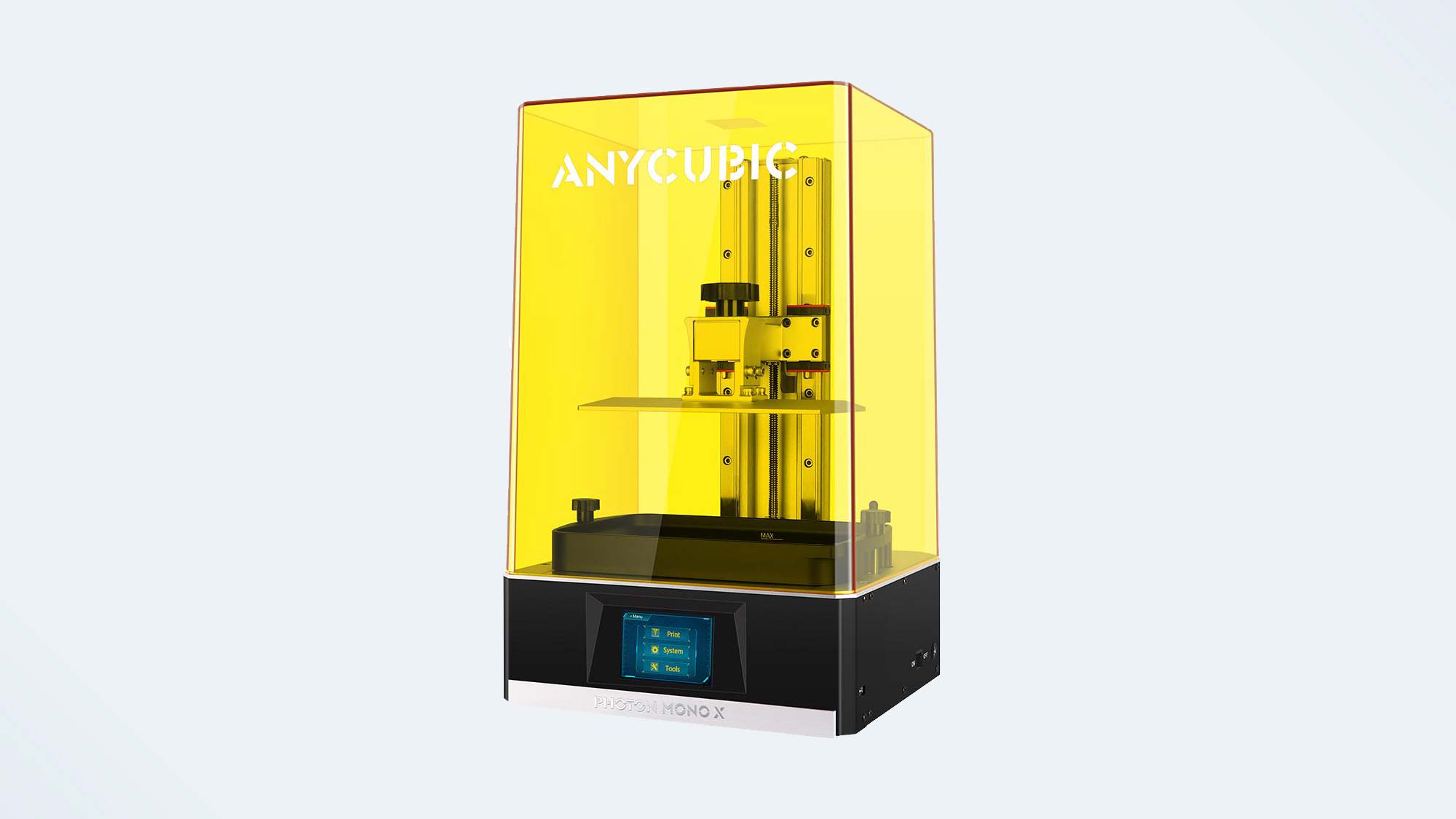

Photon Mono X 3D printer review: Design

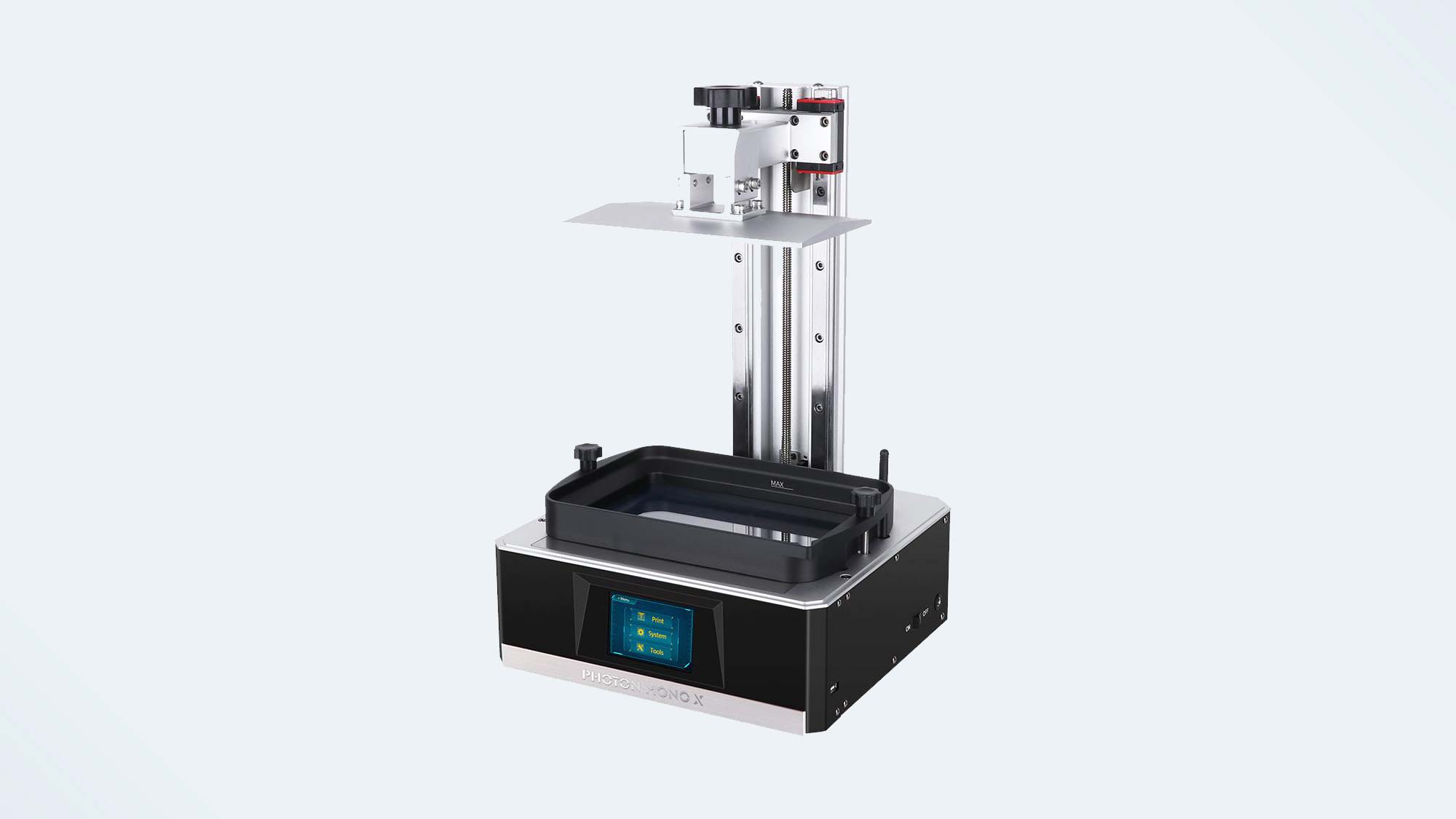

The Photon Mini Ten is a Stereolithography (SLA) 3D printer, which means it uses a low-cal source to turn a liquid resin solid. This solid fabric so sticks to the metallic print bed, which is raised, lowered, and the process repeats, creating the print layer by layer.

It's a bit more complex than the FDM (Fused Degradation Modeling) type of 3D printer, which uses melted plastic to build the layers, and then SLA printers have generally been the more expensive option. (Our favorite SLA printer, the Form 3 from Form Labs, costs $3,499.) However, SLA printers produce more complex prints with effectively particular because they produce finer layers. The default layer top for the Photon Mono 10 is 0.01mm, ten times smaller than a typical FDM printer.

At 18 inches tall and eleven.iv inches broad, the Photon Mini Ten is a small printer for the size of prints it produces: It's capable of producing 9.vi x vii.5 x 4.half dozen-inch prints — a total of 331 cubic inches. Nigh of the volume of the printer is the hood that fits over the printing surface area, made of come across-through plastic that shows you the press process, just blocks UV light from getting in or out.

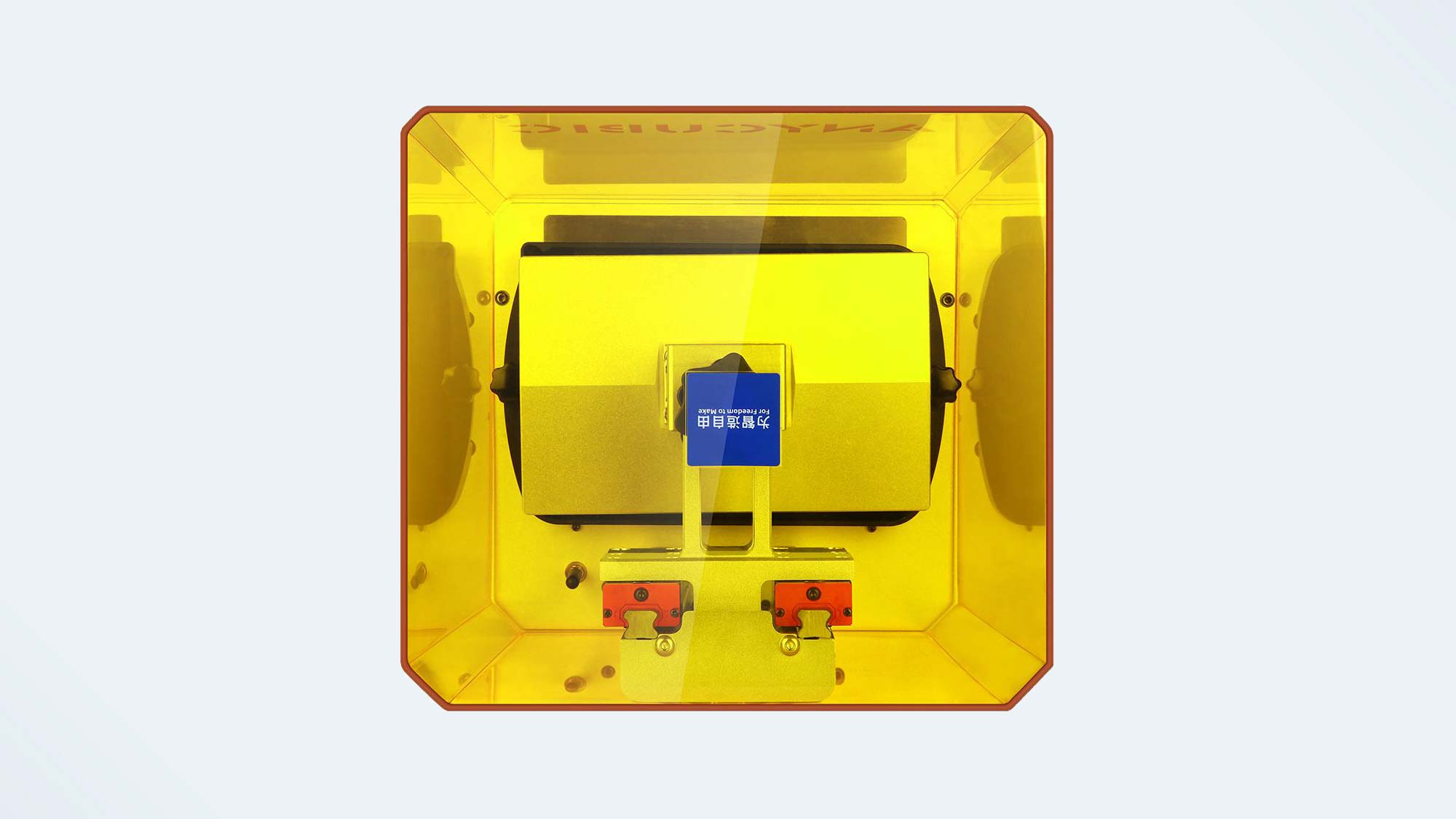

Many SLA 3D printers utilize a laser to zap the resin, but the Photon Mono X goes another route, using a panel of ultraviolet (UV) LEDs with an LCD screen above, right below the tank that holds the resin. This works like the backlight on your HDTV: the lite shines through the LCD screen where each pixel is turned and blocked where each is turned off. The screen has a 4K resolution (3840 past 2400 pixels), which means that each pixel translates into a infinite of less than 0.01mm on the final print. The lesser of the resin tank is a sheet of clear moving-picture show made of a material chosen Fluorinated Ethylene Propylene (FEP) that lets through the UV low-cal to solidify the resin.

Both the screen and the FEP pic require replacement after heavy use, every bit the UV light damages them over time. AnyCubic claims that the monochrome screen used in this model will last for thousands of hours of press, while the FEP sail needs to be replaced every 20 to 30 prints.

The other advantage of a monochrome screen is speed: while the colour LCD screens that are used in most SLA printers have 3 filters to let through blood-red, green, and bluish light, monochrome screens don't have any filters. That means more light gets through, so the printing is quicker. AnyCubic claims a printing speed of half-dozen vertical centimeters (about 2.3 inches) per hour, and nosotros wouldn't disagree: this is a fast printer.

The Wash And Cure Plus is the same size and shape as the printer, with a like design. Instead of the print head, there is an arm covered in UV LEDs which bends at the end to encompass the entire impress. A removable vat for washing is also included; it includes a built-in agitator to stir the liquid.

Photon Mono Ten 3D printer review: Impress process

The prints that the Mono X produces are set up in the Photon Workshop software, available as a complimentary download for Windows and OSX. Information technology'due south a decent if slightly quirky 3D slicer that allows you to load 1 or more 3D models and prepare them up for printing. The models can be moved, multiplied, and scaled up and down, the saved for printing. You can't create new models in Photon Workshop, though.

The Photon Workshop tin can automatically add the supports, the tree-like structures that hold the print in place while information technology is being produced, and which are removed later. This didn't prove to exist too successful, though: several of our print failures were caused by incorrectly placed supports, and I found that I would usually exercise the automatic supports, and then get through and manually add together more than to the places on the impress that might accept bug.

One interesting characteristic hither is the ability to divide models. If a model is too big to print at once, Photon Workshop tin separate it into pieces. Each piece is and so printed in turn and stuck together. That's a nice fox that would be practiced to see on other slicer apps.

At that place is also an Anycubic app available for Android and iOS that yous tin can use to start a print or monitor print progress from your telephone. Y'all tin can't upload a impress file from this app, but it is dainty to have a way to see how far a print has to go before it's washed. Fifty-fifty nicer would be a camera to evidence you if the impress is working properly, but that isn't present on the Photon Mono Xr.

One time the print is complete, you use the Wash and Cure Plus to — equally the proper noun suggests — wash the print to remove any liquid resin and cure it to solidify the resin with UV light. Firstly, you wash the print in isopropyl booze, which can be done either after you remove the print from the print bed or mountain the unabridged print bed onto i of two slots in an included handbasket. This large container holds a lot of liquid — upwards to 8.5 liters (2.25 gallons). You won't always need that much, simply yous will need enough to cover the print completely. At the moment isopropyl alcohol is not cheap, as it is one of the primary ingredients of mitt sanitizer.

When the print is in place, y'all select how long you desire it to be washed for, then press the control dial in to start. The agitator stirs the liquid, changing direction every ii minutes to brand certain that all of the cracks and crevices of the impress are washed.

In one case your print is washed, you remove the print and let it dry. After that, it is fourth dimension to cure the impress, which you do by replacing the alcohol container on the Wash and Cure Plus with a rotating platform. Again, yous use the command dial to select how long to cure for: typically, this would exist 2 to 5 minutes, depending on the size of the impress.

One time you start the process, the platform rotates exposing the print to the UV light from the LEDs on the arm that towers over the impress. The process won't start until yous replace the plastic cover, which blocks the UV low-cal from coming out. That'due south a good precaution, as this intensity of UV light tin can damage your eyes.

Photon Mono X 3D printer review: Print speed

The Photon Mono 10 is a speedy printer: our 4-inch high Thinker test model took 7 hours and 35 minutes to print, which is significantly faster than most printers in this class. The Peopeoly Phenom, for instance, took simply over 13 hours to print the same model at the same size.

We unremarkably impress the Thinker model vertically to make it fair for printers that don't have enough space on the build plate to print the Thinker lying down horizontally. The Photon Mono X has plenty of impress space large plenty to handle this, so nosotros also tested this and found out that it was much, much quicker, taking just 3 hours and 56 minutes to impress in this direction.

Photon Mono X 3D printer review: Print quality

I was impressed with the quality of the prints that the Photon Mono 10 produced. My prints had clean, precipitous edges and polish, organic curves and surfaces. Nosotros test using three models that test the ability of the printer to reproduce details: a scan of Rodin's Thinker, a prepare of planetary gears, and a geometric sculpture.

The Thinker statue was mostly well reproduced, with fine details and smooth, organic curves that looked like the real matter on the head and shoulders. The Geometric sculpture had precipitous, clean edges with nice points and accurate interlocking surfaces. The Gears were hands assembled and ran smoothly, although the grayness resin we tested with this printer produced a lot of dust and residue (the white material) when we screwed the diverse parts of the gears together.

We did discover some problems on prints, though: sometimes, some of the layers seemed to come up loose, leading to loose flaps of resin. Look, for example, at the keg in the horizontal print of the Thinker: the inner dogie of his right leg has a few layers that didn't stick to the ones higher up. Likewise, ane of the points of the geometric sculpture seems to exist flattened considering the layers were pushed downwards past the liquid resin as the impress was produced.

Almost of these issues tin can be corrected by tweaking the print, though: the loose layers and the squashed point point that the print required a few more than supports to concur it in identify while press, or that the object might be amend printed at a different angle.

All of this indicates something that is true of almost 3D printers: they still require a lot of tweaking to get the best quality prints out of them, and much of this tweaking relies on working out why a print failed and trying again.

Photon Mono Ten 3D printer review: Verdict

The AnyCubic Photon Mono 10 breaks new basis, pushing downward the cost of SLA printing to a new depression. It does and then without making likewise many compromises: printing remains a slightly messy business that occasionally fails, but once y'all get used to the Photon Mono X (and buy a mask and a big box of disposable gloves), it is generally hassle-free and fast.

SLA press is definitely still a process that requires patience, though, as some prints from the Photon Mon Ten failed and crave amending and re-printing. I would as well recommend that you buy the Wash and Cure Plus, equally information technology makes the rather disgusting business of cleaning and curing SLA prints much easier.

Combined, the two cost less than $800 and can produce large, loftier-quality prints at a faster speed than most of the competition. The Form 3 remains the SLA printer to become for professionals who need to practise a lot of heavy-duty printing, just the Photon Mono Ten is an excellent pick for at-home work by hobbyists or those curious about 3D printing.

Source: https://www.tomsguide.com/reviews/photon-mono-x-3d-printer

Posted by: grantpeong1995.blogspot.com

0 Response to "Photon Mono X 3D printer review: The best resin printer we’ve tested under $1,000"

Post a Comment